Llámenos

+86-19858305627

Envíanos un correo electrónico

sales@maple-machinery.com

Piezas de fundición a la cera perdida de acero para válvulas Fabricantes

Nuestra fábrica ofrece fundición en arena, forjado en matriz cerrada, forjado en matriz abierta, etc. Diseño extremo, materias primas de calidad, alto rendimiento y precio competitivo es lo que todo cliente quiere, y eso es también lo que podemos ofrecerle. Tomamos alta calidad, precio razonable y servicio perfecto.

Productos

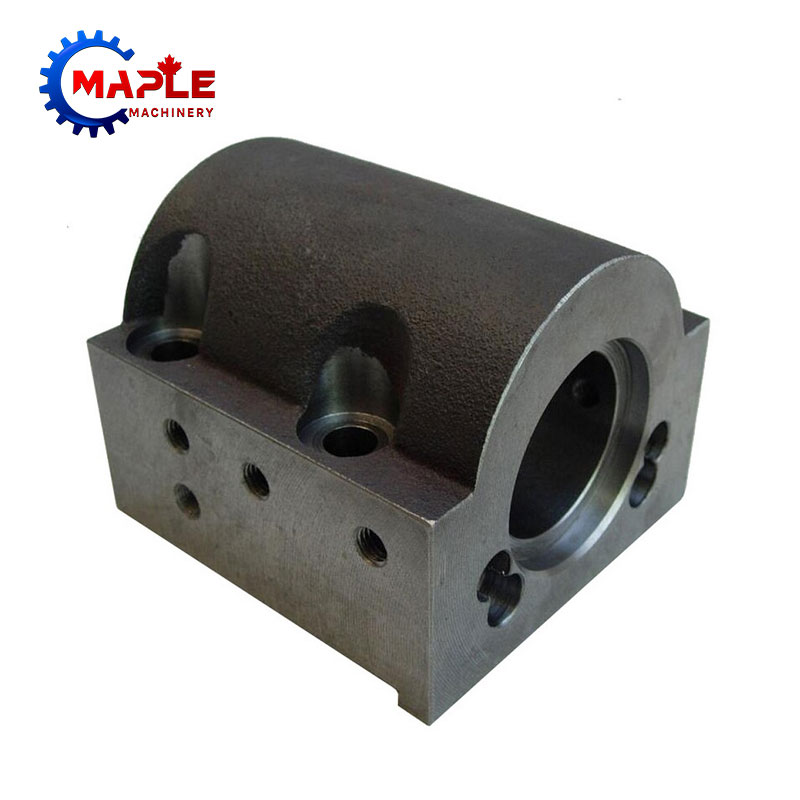

Piezas de fundición de hierro gris para la industria todoterreno

La cooperación de Maple Machinery con los clientes de Off Highway Industry Grey Iron Casting Parts es nuestro mayor activo. Como equipo apasionado por los productos de fundición de hierro gris, hacemos todo lo posible para satisfacer las expectativas de nuestros clientes. Agregue valor, con el mejor rendimiento de costos Piezas de fundición de hierro gris de la industria fuera de la carretera, junto con una cadena de suministro confiable que produce productos de la más alta calidad.Piezas de fundición de cera perdida de acero de la industria fuera de la carretera

Maple machinery has a number of casting plants, with strong processing capacity Specializing in the production of carbon steel, alloy steel, stainless steel, high temperature alloy and other wax lost casting parts and machining parts. Maple's superior quality of Off Highway Industry Steel Lost Wax Casting Parts attracts equally excellent customers, enabling our products to serve various machinery industries. 产品内容 Off Highway Industry Steel Lost Wax Casting Parts Product Introduction Off Highway Industry Steel Lost Wax Casting Parts is a product that Maple machinery has been doing. Lost wax casting is now called investment casting. It is a precision casting process with little or no cutting. It is not only suitable for precision casting of various types and alloys, but also produces castings with higher dimensional accuracy and surface quality than other precision casting methods. In order to meet the needs of different customers, we use two kinds of wax, namely yellow low temperature wax and green medium temperature wax. 2. Product Parameter (Specification) Item Off Highway Industry Steel Lost Wax Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel/Casting Iron Certification ISO 9001:2015 Weight 0.01-5000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Sand Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Services for Off Highway Industry Maple machinery has been increasing its manufacturing capacity for Off Highway Industry Steel Lost Wax Casting Parts for many years. Provide high quality Off Highway Industry Steel Lost Wax Casting Parts for our machining operations to meet and satisfy customer needs. We are able to process different types of castings, including: pressure die casting and sand castings. We assist our customers to select the most appropriate casting type according to the required volume and complexity, providing the most cost effective solution. The railway sector provides a crucial network for transport and distribution. It needs cost-effective and long-lasting equipment that is dependable for the range of applications. The railways, from freight to passenger, need different castings for various applications. Maple Machinery carries extensive experience to create steel castings and iron castings in varying sizes, shapes, and materials that are precise, strong, and durable. We manufacture a wide range of castings and forgings for railway infrastructure and transportation equipment. 4.Supporting Service for Off Highway Industry parts As mentioned above, in order to work in adverse conditions, the performance of the Off Highway Industry Steel Lost Wax Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Off Highway Industry parts We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Off Highway Industry Steel Lost Wax Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for the Off Highway Industry We have manufactured a wide range of Off Highway Industry Steel Lost Wax Casting Parts. The following are typical products: Coupling components, Centre plates, Bearing brackets, Rail wheels, Wheel hub, Base plate, Axle boxes, Yokes, Pedestals, Hinges, Tie plates, Side jaw clip, and Joint bar. 6. Why Sand Casting Sand casting is an ancient casting process where the metal parts are molded by pouring metal into a hollow cavity. The mold-based manufacturing process is used to make castings with materials of iron, steel, and Aluminum. Casting-based manufacturing includes several steps and can create a wide range of shapes and sizes for metal products. The process begins with the making of a mold pattern and a gate system with the exact size and shape of the required part. The temperature required depends on the metal as some metals take a long time to heat and melt. Maple Machinery has continuously upgraded its Sand-casting equipment and refined the casting process. The aim behind this is to use only the advanced casting technology for its Sand-casting operations. Each step follows the customer’s drawings and instructions to deliver precise solutions.Piezas de forja de troquel cerrado de acero de la industria fuera de la carretera

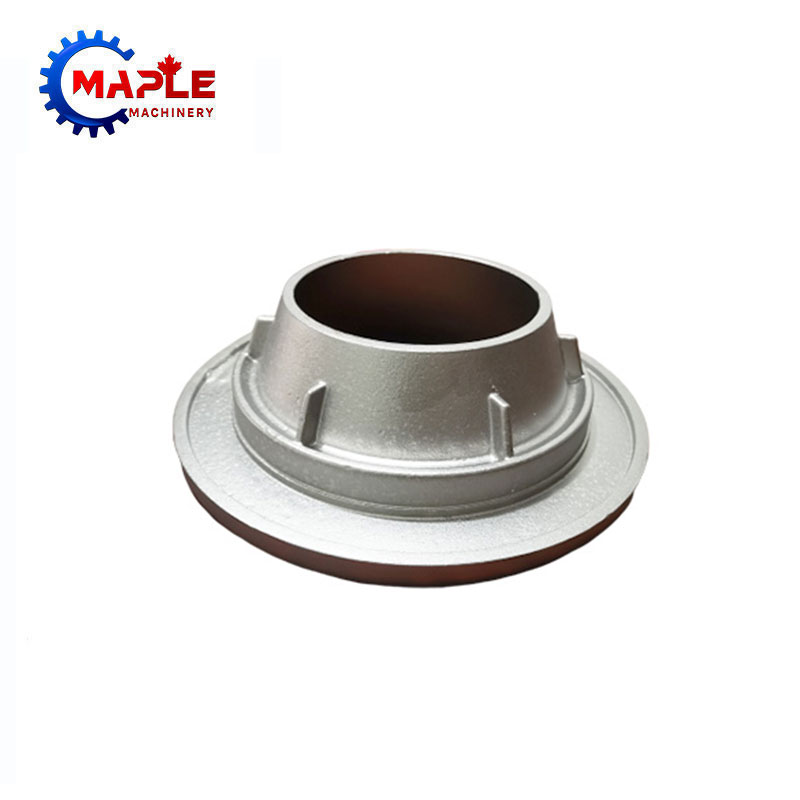

MapleMachinery se especializa en la producción de piezas forjadas con matriz cerrada. Nuestros productos incluyen piezas forjadas de metal como aluminio, acero al carbono, acero aleado y acero inoxidable, que se utilizan en las industrias fuera de carretera, agrícola, automotriz, de construcción y minera. Proporcionamos piezas de forja de troquel cerrado de acero para la industria todoterreno de alta calidad y el mejor costo total para superar las expectativas del cliente.Piezas de forja de troquel cerrado de acero marino

Para asegurar la solución más viable para los proyectos de nuestros clientes, Maple Machinery cuenta con una planta de fabricación con las más modernas Piezas Forjadas en Matriz Cerrada de Acero Marino, asegurando que cumplan con todos los parámetros y especificaciones requeridas por nuestros clientes. Satisfacer las necesidades del cliente, etc. para lograr la satisfacción del cliente.Piezas de forja de acero inoxidable para la industria todoterreno

La maquinaria de arce ofrece a los clientes una amplia gama de piezas de forja de acero inoxidable para la industria todoterreno. Nuestra principal competencia es el desarrollo de soluciones de sistemas específicos para el cliente para la industria todoterreno a fin de satisfacer los requisitos más exigentes. Además de volumen, precisión, seguridad y confiabilidad, nuestros clientes buscan cada vez más tecnología superior y eficiencia económica.Piezas de fundición de hierro gris de la industria minera

Maple Machinery es un fabricante de piezas de fundición de hierro gris para la industria minera. Proporcionamos productos, productos metalúrgicos especializados y equipos de producción, y brindamos el apoyo de consultoría necesario. Con más de 15 años de experiencia en estas industrias, podemos ayudar a encontrar la mejor tecnología y equipo para los procesos de fundición y tratamiento de superficies de hierro gris.

Enviar Consulta

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy